In most cases, inventory is a distributors single largest asset so it’s critical for a

distributor to understand what they have in stock and what they need to serve their existing and

prospective customers.

When you don’t have the right inventory, you risk upsetting your good customers, tying up cash

on worthless inventory, and missing sales opportunities with new customers.

The Interlynx Inventory Management System will help you understand your inventory, identify slow

(or non) moving inventory, customer dependency, returnability, profitability and help you make

better choices on what to stock.

All of our systems are designed specifically for distributors – affordable, useful and simple to

use.

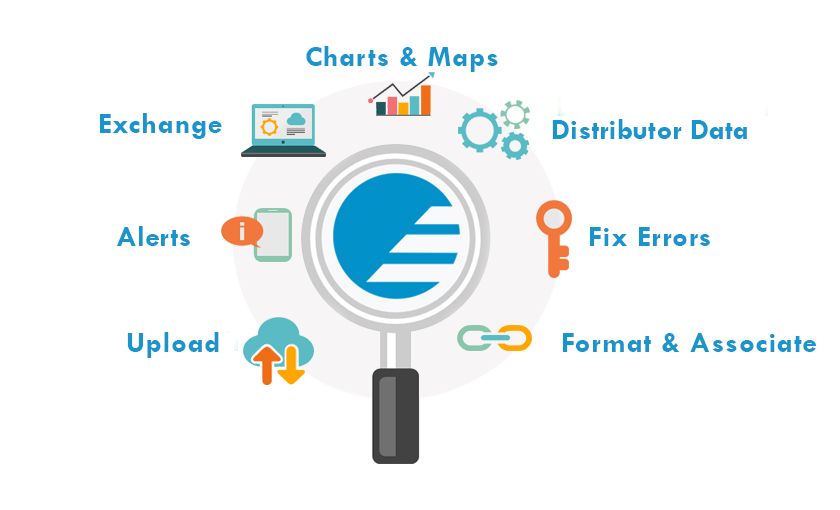

Your distributors will send their inventory level via API, flat file or other means in real time

or on a schedule time iteration and in their preferred format.

Interlynx will then take the raw data, fix, format and associate each SKU with the

manufacturer’s product family structure.

The inventory data from each distributor will be uploaded into a consolidated database.

The entire process will be captured in a suite of reports with alerts even the ability to

“exchange” inventory information between manufacturer and distributor or between distributors.

Identify and track distributor inventory levels

Identify trends in the data to assist in production planning

Optimize field inventory and keep in balance.

Help distributors to move slow moving inventory.

Drive distributor mindshare by helping them win.

Drive financial efficiency and reduce waste.